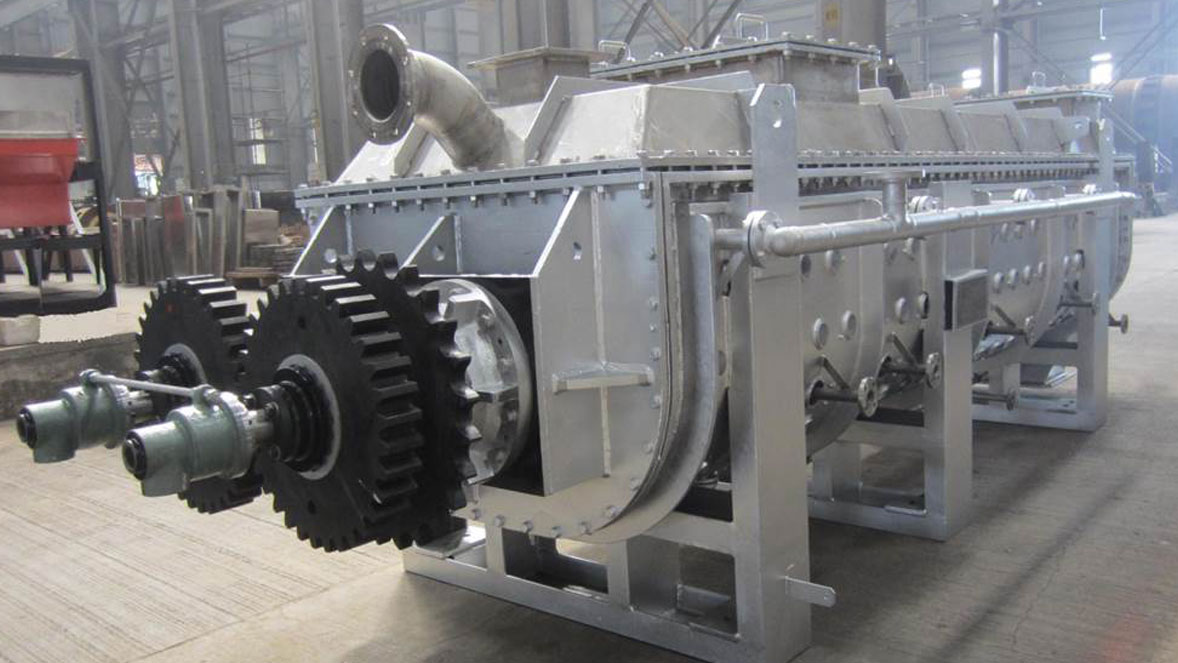

A paddle dryer is a heat transmission dryer, equipment that processes organic and inorganic granular and powdery materials. It dries/cools these materials by bringing them into direct contact with revolving, cuneiform shaped hallow heater (paddles) without using gas as a heating medium.

Heat transfer from heating medium to the material is by conduction. Efficient drying of powdery/crystalline/ granular material is achieved by bringing it in direct contact with revolving cunie form hollow paddles, without using any gas as heating medium. The trough is uniformly heated by passing heating medium through the jacket. This ensures that the entire material in the dryer is in full contact with the total heat transfer area during its passage through the dryer.